-40%

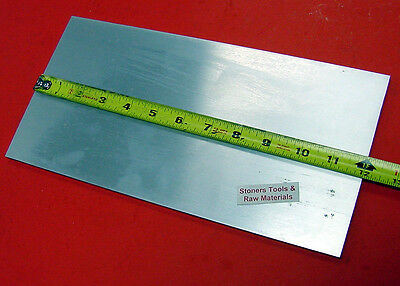

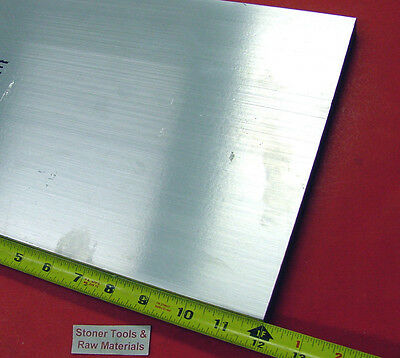

Kovar ASTM-F-15, 12x16” .0075 Ed Fagan/NEA sourced aerospace quality

$ 58.08

- Description

- Size Guide

Description

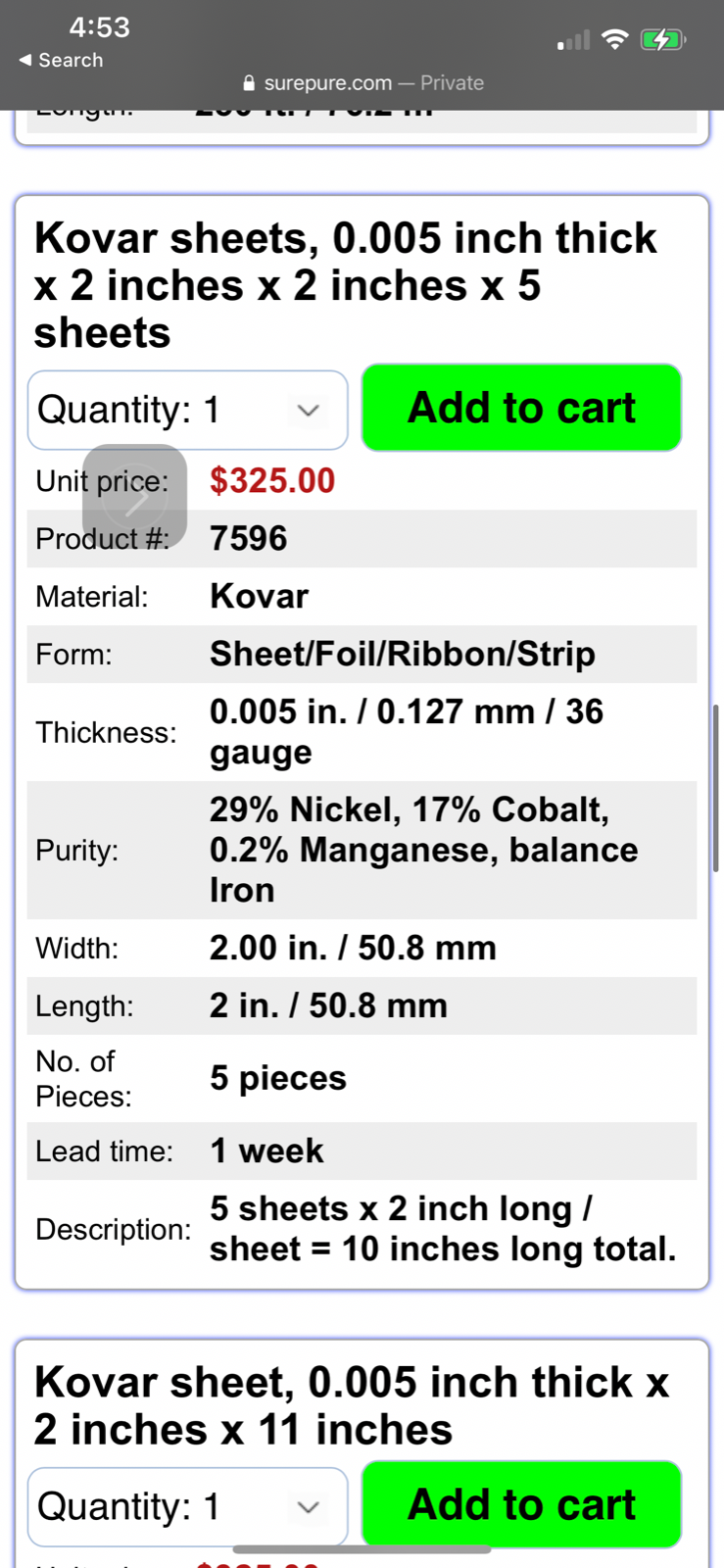

I am glad to make these available to the hobby and home manufacturing diy community which usually has such materials prohibitively expensive at this quality as single sheets of .005 and above can reach 325 dollars for a mere 2x11 inch sheet and such sources are not top quality oftentimes AND their shipping times are much longer than ours often at weeks for fulfillment. No wait times for quotes or purchase order pains here. Experiment and engage in more fulfillingR&D.

Sourced from NEA and Ed fagan, and parameters are superior to those of Alibaba.com suppliers where phase transformation is not only below industry standard of -80 but highly variable and thus not backed by any guarantees... this notwithstanding its NEA source, the sheet is being made available as is and may be subject to extremely minor deformation or corrosion, but in such cases I will be sure to first contact the buyer and this will be out fo the ordinary as I have many sealed crates still bound in metal straps contained in an environmentally stable area.

Nickel Iron Cobalt/Kovar

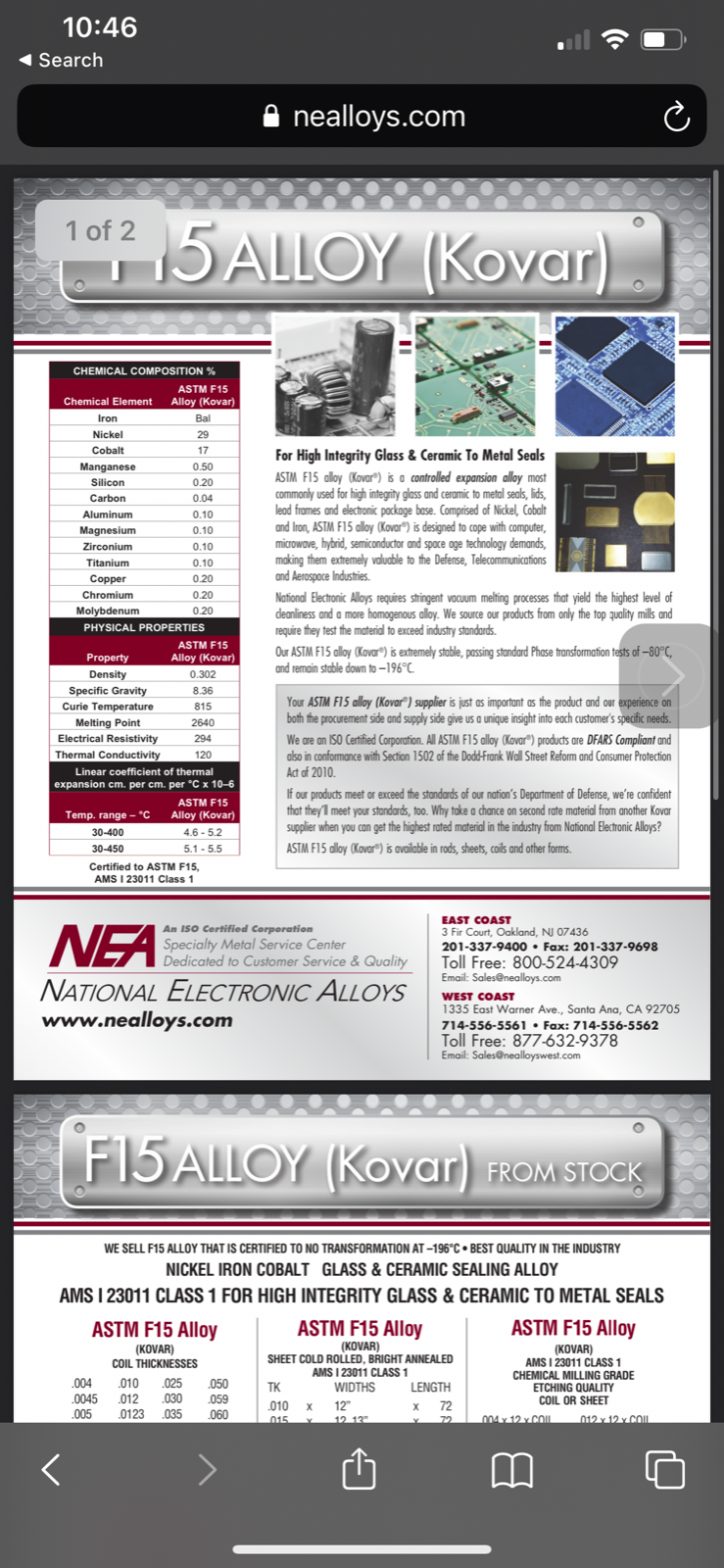

Kovar, also known as

ASTM F 15 Alloy

, is a

controlled expansion alloy

that is typically applied to high integrity glass and ceramic to metal seals, lids, lead frames and electronic package base. Kovar is made of nickel, cobalt and iron. This alloy is designed to adapt to computer, microwave, hydrid, semiconductor and space age technology demands, thus, making this an essential resource to the

defense

,

aerospace

and

telecommunications

industries.

National Electronic Alloys requires stringent vacuum melting processes that yield the highest level of cleanliness and a more homogenous alloy. We source our products from only the top quality mills and require they test the material to exceed industry standards. Our ASTM F15 alloy (Kovar©) is extremely stable, passing standard Phase transformation tests of -80°C, and remain stable down to - 196°C.

Your

ASTM F15 alloy (Kovar©) supplier

is just as important as the product and our experience on both the procurement side and supply side give us a unique insight into each customer’s specific needs. We are an ISO Certified Corporation. All ASTM F15 alloy (Kovar©) products are

DFARS Compliant

and also in conformance with Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act of 2010. If our products meet or exceed the standards of our nation’s Department of Defense, we’re confident that they’ll meet your standards, too. Why take a chance on second rate material from another Kovar supplier when you can get the highest rated material in the industry from National Electronic Alloys? ASTM F15 alloy (Kovar©) is available in rods, sheets, coils and other forms.

National Electronic Alloys has Kovar available immediately for your usability.

Contact us

at your convenience for pricing and order inquiries.

Kovar Applications: Electronic Package Base, Lids, Lead Frames & Glass to Metal Seals.

Industries Served:

Telecommunications

,

Aircraft & Aerospace Industry

, Military and Defense,

Semi-Conductor & Microwave.

Learn more about Kovar

F15 ALLOY

WHEN YOU BUY KOVAR

PRICE VS. QUALITY

MACHINABILITY DATA

ADDITIONAL KOVAR DATA

METAL FROM STOCK FLYER

NICKEL IRON ALLOY COMPARISON CHART

TYPICAL NOMINAL CHEMISTRY

NICKEL (Ni)

29.0

COBALT (Co)

17.0

MANGANESE(Mn)

0.50

SILICON (SI)

0.20

SULFUR (S)

0.025

CHROMIUM(Cr)

0.20

COPPER (Cu)

0.20

MOLYBDENUM (Mo)

0.20

ZIRCONIUM (ZR)

0.10

PHOSPHORUS (P)

0.025

CARBON (C)

0.06

IRON

BALANCE

TYPICAL TENSILE STRENTGH

ANNEALED

85,000 MAX

1/4 HARD

90,000 TO 115,000

1/2 HARD

105,000 TO 125,000

HARD

120,000 MIN.

TYPICAL HARDNESS, ROCKWELL B

ANNEALED

85 MAX

1/4 HARD

90 TO 93

1/2 HARD

94 TO 96

National Electronic Alloys

material is tested and certified to exceed industry standards on Phase Transformation, making it the most stable material available.

TYPICAL LINEAR COEFICIENT OF THERMAL EXPANSION

(cm per cm. C x 10-6)

30 to 100

N/A

30 to 200

5.5

30 to 300

5.1

30 to 350

N/A

30 to 400

4.9

30 to 425

N/A

30 to 450

5/3

30 to 500

6.2

30 to 550

N/A

30 to 600

7.9

30 to 700

9.3

30 to 800

10.4

30 to 900

11.5

30 to 1000

N/A

No Phase Transformation to -196°C

National Electronic Alloys

material is tested and certified to exceed industry standards on Phase Transformation, making it the most stable material available.